Overview of Pumping Operations

The sand collection system is the key to the successful operation of this project. It has been designed for efficient operation, low operating costs and low maintenance requirements and is similar in design to the Sand Bypassing System at the Gold Coast seaway.

The system comprises of a sand collection jetty with an overall length of 450 metres constructed perpendicular to Letitia Spit Beach. A sand trap has been developed under the jetty by the operation of a series of ten submerged jet pumps. The sand trap is maintained as a permanent depression under the sand collection jetty to allow natural processes to feed sand into this trap from the natural littoral drift of sand northwards along the coastline. In the early stages of operation, the accumulated sand reserve on Letitia Spit, caused by the extension of the entrance training walls in the 1960s, was also used to supply the sand traps.

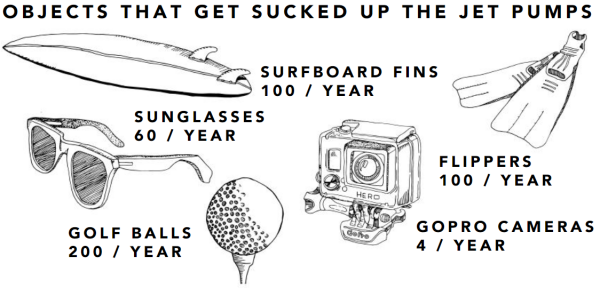

The system has been designed to operate with up to four jet pumps working together at the same time. The jet pumps are run on water drawn from the Tweed River. The sand slurry produced is transported through a flume to a slurry pit located on shore. A screening device is provided to prevent large items (shells, bricks, stones etc.) picked up by the jet pumps from reaching and blocking the sand transfer system.

These items are collected in a separate waste bin and disposed of appropriately. The slurry pit receives the sand slurry from the flume and concentrates the slurry to the required density. Surplus water from the slurry pit overflows through an underground 750 mm diameter stormwater drain to the Letitia Spit Beach.

The discharge of each jet pump is monitored for slurry density to enable the operating jet pumps to be switched when the sand supply at each jet pump is exhausted. The use of jet pumps to collect and transport the sand from the sand trap eliminates the need for major plant items on the jetty, thereby reducing the risk of environmental damage. This simplifies the functions of the sand collection jetty to: providing access over the sand trap area; and supporting the required pipework in such a way as to ensure the safety of jetty users during operations. Maintenance requirements are also reduced, as all large plant items are located in protected environments. Platforms are provided at the jet pump locations for maintenance purposes.

The jet pumps are operated using high-pressure water drawn from the Tweed River upstream of the entrance. Here, water free from sand, can be reliably obtained to reduce wear in the water pumping equipment. Clean salt water is collected at the low-pressure pump station, which comprises of one submersible pump supported in the Tweed River on a steel piled structure (refer pipeline network ). Screens at the pump inlet prevent large items from being drawn into the pump. The low-pressure water is delivered to the control building via an underground 600 mm diameter pipeline to supply the high-pressure pump, which in turn supplies the jet pumps on the jetty.

A single high-pressure pump driven by a variable speed motor supplies the high-pressure motive water for the jet pumps. The pump speed is adjustable and limits the maximum volume of sand delivered by the jet pumps to match the capacity of the sand transfer system. The control system automatically cycles combinations of the jet pumps to maintain the sand trap and optimise the sand delivery rate.

Once sand is collected in the slurry pit it is pumped through a 400 mm diameter polyurethane lined steel (cathodically protected) slurry pipeline under the Tweed River to a chosen outlet (refer to pipeline network and basis of outlet usage) that exists along the southern Gold Coast beaches or at Duranbah in NSW. There are two fixed outlets (Snapper Rocks East and Snapper Rocks West) along with valve pits for the connection of temporary pipe outlets at Duranbah Beach, Coolangatta/Greenmount Beach and Kirra Point. The system is designed to discharge to only one outlet at a time – the operating outlet is selected by operating and locking valves, which are located at branches along the slurry pipelines (refer pipeline network ).

Sand slurry is pumped from one of two slurry pumps, or two pumps in series depending on which outlet is selected. One variable frequency power supply is provided and normally connected to the first pump motor. The second pump is driven by a fixed speed drive. The variable speed drive is used to vary the discharge pressure to control the pipeline operating velocity, ensuring that it remains within safe limits, and to control the maximum slurry density in the pipeline to eliminate the possibility of blockages. The slurry pumps are configured using interchangeable pipework to enable either pump to be operated alone for the closer outlets, including the main operating outlet at Snapper Rocks East. The slurry pumps can be configured to operate in series for the more distant outlets (Snapper Rocks West and Kirra Point).

The sand transfer system is continuously monitored from the control building and is designed to operate at slurry densities up to 50% by weight. The maximum slurry density applies for sand transfers to the main outlet at Snapper Rocks East and also Snapper Rocks West. Lower slurry densities may be utilised when pumping to the more distant temporary outlet at Kirra Point in order to reduce the maximum required pumping pressures.

All large plant except for the low-pressure water supply pump is located within the controlled environment of the sand bypassing system pump hall and control building. Computerised controls operate the entire system (excepting for outlet selection which is manual) and maintain full records of all operations including the number of hours pumped and sand quantities pumped to each outlet.